أنت هنا .. Home / Why chosse the High Speed Automatic Straight Type Bottle Blow Molding ... Why chosse the High Speed Automatic Straight Type Bottle Blow Molding Machine?

- Embryo system: adopting a single slide type structure for embryo implantation, and the cylinder double-channel pushes the embryo release, which effectively solves the problem of wear between the stuck embryo and the preform

- Transmission system: Adopting Taiwan KMC chain, driven by servo motor, make its heating unit stable in movement, fast and accurate positioning.

- Heating system: Use infrared lamp tube to heat the preform to make stretching more uniform and transparency; the imported reflective aluminum plate is equipped to make full use of the heat energy of the lamp tube, shorten the heating time, reduce energy consumption, increase productivity. Each lamp on the floor can adjust the temperature individually, and can be adjusted up and down and back and forth according to different tube blanks of customers.

- Mold system: adopts high-pressure mold clamping technology, no mold expansion phenomenon, and the mold clamping line is thin. The mold adopts a drawer structure. The four drawbars fixed on the mold back plate are positioned and can be easily replaced within half an hour.

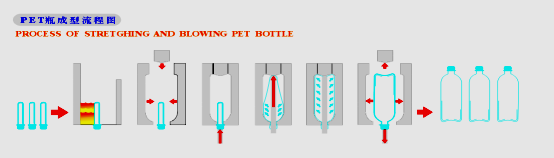

- Stretching and blowing system: using stretching high-pressure sealing combined cylinder, the cycle time of one-blowing and two-blowing can be adjusted, each pulling rod can be adjusted individually according to different tube blanks and different bottle types of customers, with high flexibility

- Electronic control system: Pneumatic and electrical components are all well-known international brands, the touch screen control system is easy to operate, has perfect monitoring and induction settings, fault diagnosis function, automatic calculation report function, master the production efficiency of each shift

- Cooling/chilled water circulation system: There is a cooling water channel under the heating box. When the preform is heated, the cooling water channel is used to block the heat of the lamp tube to protect the tooth mouth from deformation. Cool the mold quickly to improve the productivity of the whole machine