Water Purification Face-Off: RO vs EDI

When designing a bottled water line, the choice between Reverse Osmosis (RO) and Electrodeionization (EDI) is fundamental. Both achieve high purity, but through entirely different scientific principles.

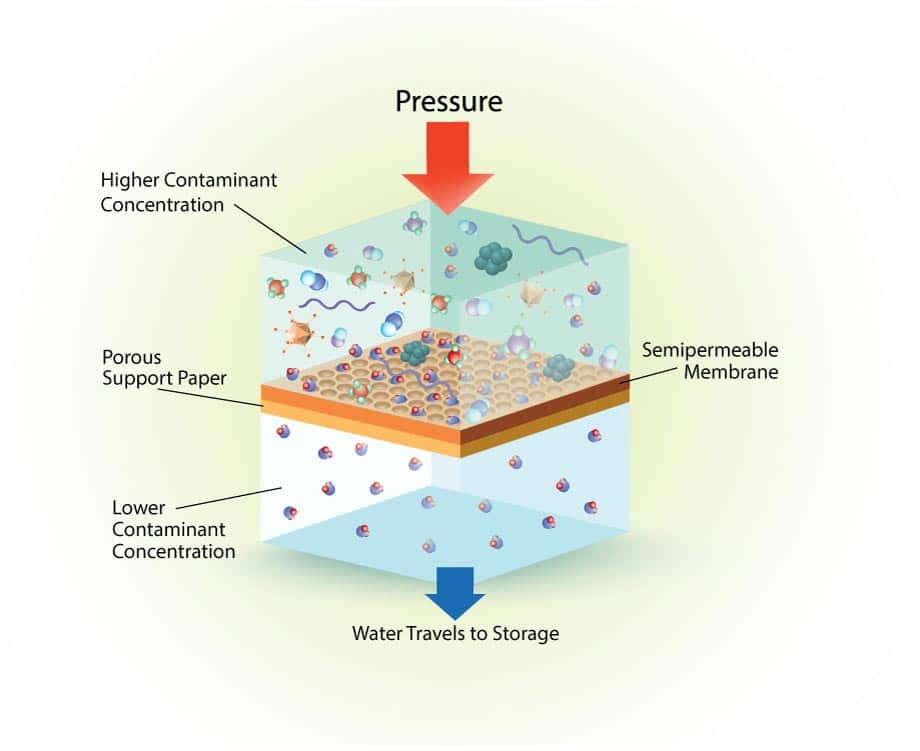

Think of RO as a supremely selective membrane. It forces water through microscopic pores under pressure, physically blocking dissolved salts, organics, and pathogens. It’s the robust, energy-driven workhorse for producing safe, consistent drinking water, perfectly suited for brands where a controlled mineral profile is key. Our ShineDew RO-5000L System exemplifies this, reliably serving medium-capacity mineral water production.

EDI, however, operates on an electrochemical principle. It uses direct current to continuously regenerate ion-exchange resins, splitting water molecules to create H+ and OH- ions that displace and flush out mineral ions. This chemical-free process polishes water to ultra-pure levels, ideal for applications requiring near-zero dissolved solids or for brands targeting the highest purity standards.

The Strategic Choice:

Opt for RO to craft natural mineral water or premium purified drinking water with desired mineral content.

Combine RO+EDI when your target is laboratory-grade purity or you supply industries with stringent ionic contamination limits.

At ShineDew, we help you navigate this critical decision—not with a one-size-fits-all solution, but with the precise technology for the water you envision.