21 Preservation Secrets in Bottle Caps!

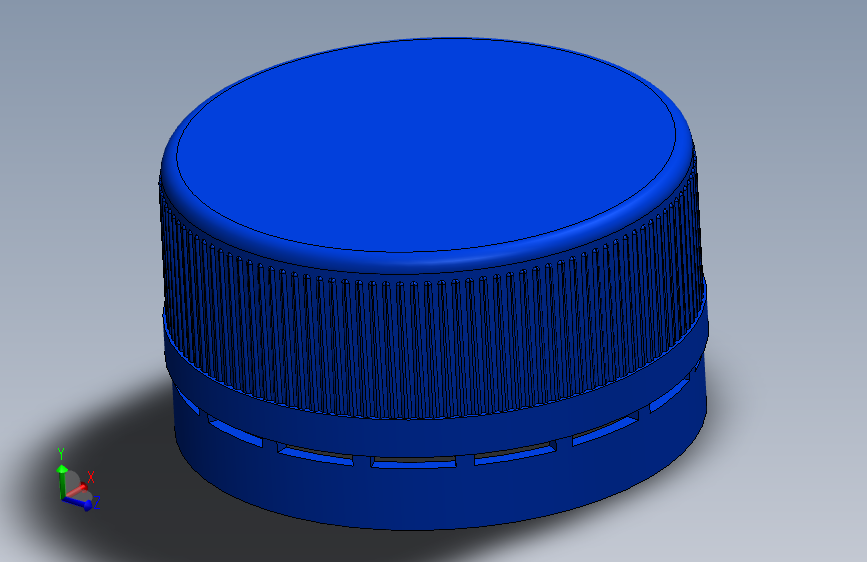

In supermarkets, bottled water is often labeled with “shelf life of 24 months”. The guardian behind this is not the preservative, but the seemingly ordinary thread on the bottle cap! These 21 threads are no decoration – each with a precise Angle of 55° to 60° can generate just the right radial pressure when tightened, forcing the elastic body inside the bottle cap to deform and form a continuous “invisible sealing band”, firmly locking the microorganisms outside the bottle.

The secret is also hidden in the bottle material: The five-layer composite PET structure makes the molecular gap astonishingly small, allowing less than 0.0001cc of oxygen to penetrate each day (about the size of half a sesame seed), effectively delaying the changes in water quality. The ultimate weapon of modern filling lines is the negative pressure capping technology: first, the residual air in the bottle is evacuated, then nitrogen is injected to isolate oxygen, and finally the cap is precisely screwed on under vacuum conditions. Swiss laboratory tests have proved that the number of colonies in water treated with this process is only 1/2000 of that in water with ordinary caps after three years.

This microbial defense system is moving from high-end water production lines to the general public. The next time you unscrew the bottle

cap, be sure to pay attention to those fine threads – they are precisely the time warriors that silently guard the water quality.