From Preform to Perfect Container: How Blow Molding Technology Shapes Our Daily Beverage Packaging

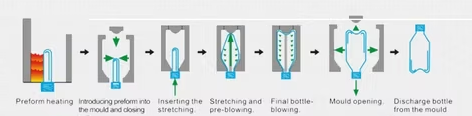

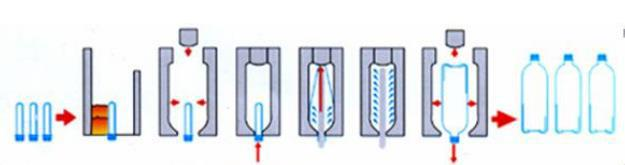

The mineral water, carbonated drinks, juices, and cooking oils we consume daily are housed in lightweight yet durable PET plastic bottles. Have you ever wondered how these standardized, capacity-varying bottles are created? The answer lies in a precise and efficient manufacturing process known as blow molding. At its heart is the blow molding machine—an invisible sculptor that transforms test-tube-like preforms into the familiar containers we recognize. The choice of blow molding machine largely depends on two key concepts: constant pitch and variable pitch.

Constant Pitch Blow Molding Machines: The Robust Foundation of Standardized Production

As the name suggests, constant pitch blow molding machines feature a fixed center distance between mold cavities. This design delivers exceptional operational stability and production consistency, making them particularly suitable for long-duration, high-volume manufacturing of specific bottle sizes. Common pitch specifications correspond directly to mainstream bottle capacities: a 76.2 mm pitch specializes in small bottles under 600 ml (such as juice bottles); a 95.25 mm pitch dominates the market for medium bottles up to 1.5 L (like standard mineral water bottles); and a 114.3 mm pitch reliably produces large bottles around 2 L (such as family-sized beverage containers).

95.25mm

Choosing a constant pitch machine means opting for an efficient, reliable, and easily maintained production line. Its heating system and blowing cycle are deeply optimized for fixed bottle designs, ensuring uniform wall thickness and excellent physical properties. For large-scale water plants or beverage brands with relatively fixed product lines that pursue maximum production efficiency and the lowest per-unit cost, constant pitch blow molding machines often represent the most cost-effective choice.

Variable Pitch Blow Molding Machines: The Modern Engine of Flexible Production

In response to increasingly diverse market demands, variable pitch blow molding machines offer a different solution. The spacing between their mold cavities can be adjusted, enabling flexible layouts such as “1-out-of-4,” “1-out-of-6,” “1-out-of-8,” and even more. For example, a “1-out-of-6” variable pitch machine can achieve a capacity of up to 12,000 bottles per hour under optimized conditions.

This flexibility is its core value. It allows producers to quickly switch between manufacturing bottles of different heights and diameters on the same equipment, significantly reducing mold investment and changeover costs for multi-variety, small-batch production. Whether producing limited-edition beverage bottles for seasonal campaigns or supplying various bottled water sizes as a contract manufacturer, variable pitch blow molding machines can meet these challenges with exceptional adaptability. Of course, this versatility typically comes with a higher initial investment and greater technical demands on operators.

Making the Right Choice: Aligning Technology with Needs

There is no absolute superiority between the “specialization” of constant pitch and the “flexibility” of variable pitch—the key lies in precise alignment with your business strategy. If your focus is large-scale, continuous production of one or a few bottle designs, pursuing ultimate operational efficiency and cost control, then a constant pitch blow molding machine is your solid fortress. Conversely, if your business requires frequent responses to market changes, with a rich and rapidly evolving product line, then the production flexibility offered by a variable pitch blow molding machine will be a valuable strategic asset.

As an equipment supplier deeply engaged in the fluid packaging field, ShineDew Machinery fully understands the value of both technological paths. We not only provide solutions ranging from stable and reliable constant pitch machines to highly adaptable variable pitch systems but also, drawing on extensive industry experience, can assist you in analyzing production data and planning capacity development. We help you make forward-looking investment decisions, ensuring that every blow molding machine becomes a reliable engine driving your business growth.