The Alchemy of Speed: How Blow Molders Turn Plastic into Precision

From bottled water to cooking oil, the plastic containers we use daily all share a common beginning: a small, test-tube-like object called a preform. The transformation of this preform into a strong, perfectly shaped bottle is the remarkable work of a blow molding machine. This process is not just about inflation; it’s a precise ballet of heat, pressure, and engineering that ensures every bottle meets exact standards for durability and safety.

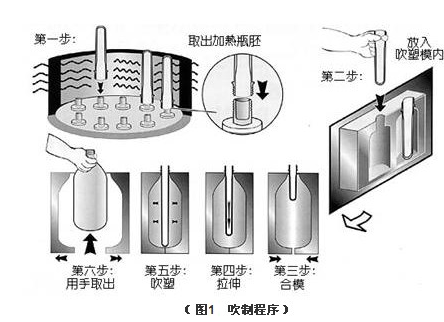

The magic happens in a two-stage sequence within the machine’s mold. First, the preform is heated to a specific temperature to make it pliable. Then, a stretch rod extends vertically to stretch the preform to the mold’s length. Immediately after, high-pressure air is injected, forcing the softened plastic to expand radially and take the exact shape of the mold cavity. This biaxial stretching (lengthwise and sideways) aligns the plastic molecules, resulting in a final product with superior clarity, strength, and barrier properties. The entire cycle, taking mere seconds, is governed by a Programmable Logic Controller (PLC) that ensures consistent temperature, timing, and pressure for uniform quality.![]()

![]()

At ShineDew Machinery, we have refined this engineering principle into reliable and efficient industrial solutions. Our blow molding machines are designed with precision controls and robust components to deliver high output with minimal energy consumption. By mastering the core science of bottle formation, we provide our clients with the technology to produce not just containers, but packaging that protects their product and enhances their brand.