The Art and Science of the Perfect Fizz: A Deep Dive into CSD Production

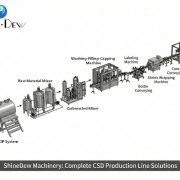

In the global beverage market, few products command as much loyal attention as Carbonated Soft Drinks (CSD). From the timeless clink of glass bottles in a village shop to the sleek aluminum cans in a high-end supermarket, the “fizz” is a universal language of celebration and refreshment. For an entrepreneur, entering the carbonated drink market—whether it’s for a traditional cola, a sparkling fruit soda, or a local tonic water—is an exciting venture. However, producing a high-quality fizzy drink is far more than just adding gas to water. it is a delicate dance of physics, chemistry, and precision engineering. If you are operating or planning a 2,000 BPH (bottles per hour) production line, understanding the journey from a simple drop of water to a pressurized bottle of joy is essential for your brand’s success.

CIP System

Every great beverage begins with a foundation of absolute purity. Since water accounts for the vast majority of your final product, its quality cannot be compromised. A professional production line starts with a comprehensive Water Treatment System. By passing raw water through quartz sand, activated carbon, and high-precision Reverse Osmosis (RO) membranes, we remove every trace of impurity, odor, and microscopic particle. This ensures that the water is a “blank canvas,” ready to accept the complex flavors of your syrup. In the mixing phase, high-grade stainless steel tanks blend this purified water with sweeteners and concentrates. For a 2,000 BPH line, consistency is the goal. Every batch must have the exact same “Brix” or sugar level, ensuring that your customers receive the same delicious experience every time they choose your brand.

The most fascinating part of the process is, of course, the carbonation. This is where we apply the science of Henry’s Law. The goal is to dissolve Carbon Dioxide (CO2) into the liquid so that it stays there until the consumer opens the bottle. The secret to a long-lasting “fizz” is temperature control. Carbon dioxide is much more stable in cold liquids. Therefore, before the beverage meets the gas, it is chilled to near-freezing temperatures, typically between 0 and 4 degrees Celsius. In our specialized Carbonator, the liquid and CO2 are mixed under high pressure. This creates a stable solution where the gas is tightly bound to the liquid molecules, preventing the drink from going “flat” too quickly once it is poured into a glass.

Mixer

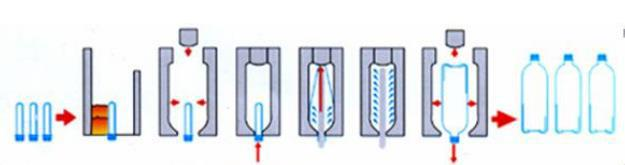

Once the liquid is carbonated, the challenge shifts to the Filling Machine. This is where precision engineering is most visible. To keep the CO2 from escaping during the filling process, we utilize Isobaric (Equal Pressure) Filling technology. Unlike still water filling, the filling valve here is the hero. During the process, the valve remains strictly closed at the start. The machine first establishes a pressure balance between the filling tank and the empty bottle. It is only when the air pressure inside the bottle perfectly matches the high pressure inside the beverage tank that the valve opens. Because the pressures are equalized, the carbonated liquid flows gently into the bottle without any violent turbulence or foaming. This “sealed-valve” approach is critical; it ensures that the gas stays in the drink and not in the factory air, guaranteeing a perfect fill level and maximum effervescence.

Immediately after the bottle is filled and capped, it moves to the final stages of the line. At this point, the bottles are often wet due to the rinsing process and the condensation that forms on the cold bottle surface. A wet bottle is a major obstacle for labeling, as adhesives cannot grip a damp surface. This is why our lines are equipped with a high-efficiency Drying Tunnel (also known as an Air Knife system). Instead of using heat, this tunnel utilizes powerful, high-velocity streams of filtered air. These “air knives” literally strip the water droplets off the bottle’s exterior, from the neck down to the base. This ensures the bottle is perfectly dry and ready for the labeling machine, resulting in a crisp, clean appearance that looks professional on any retail shelf.

Carbonated Mixer

Our company specializes in providing these technical solutions for the next generation of beverage pioneers. We designed our 2,000 BPH CSD line with a focus on reliability and “entry-friendly” sophistication. We understand that for a growing business, you need equipment that is scientifically rigorous but easy to maintain. We don’t just supply the stainless steel; we provide the peace of mind that comes with knowing your Isobaric valves are sealing perfectly and your drying tunnels are preparing your bottles for a flawless finish. From the first drop of treated water to the final dried and labeled bottle, we are your partners in bringing the world’s favorite fizz to your local market. Let’s build something refreshing together.