Efficiency Unleashed: How Intelligent Blow Molding is Reshaping Bottle Production

In the bottled water industry, blow molding machines serve as critical equipment that transforms raw materials into finished containers, with their technical proficiency directly impacting production efficiency and product quality. As market demands shift toward lightweight packaging and sustainable manufacturing, high-efficiency and energy-saving blow molding solutions have become essential.

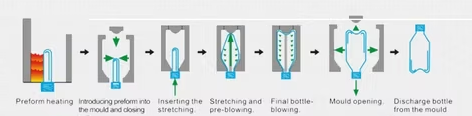

The blow molding process begins with precise positioning and transfer of preforms. Through a starwheel mechanism driven by a frequency conversion motor, preforms are smoothly fed into a semi-open energy-saving heating oven—a system that reduces energy consumption by over 30% compared to conventional designs. During the molding stage, a dual-crank mold locking mechanism, combined with high-pressure compensation technology, effectively eliminates parting line marks and ensures uniform wall thickness and structural integrity of the bottles. The integration of high-pressure valve groups with fast response characteristics further enhances the stability and energy efficiency of the blowing process. The machine features a linear human-machine interface design that supports quick mold changes and automated bottle ejection, enabling seamless integration with downstream filling lines for continuous production.

The ShineDew SD2000-6 model is specifically optimized for 1.5L mineral water bottles. Its standardized configuration and modular structure ensure compatibility with existing production lines while significantly reducing maintenance costs. As a technical service provider with extensive experience in liquid packaging equipment, we continue to offer globally competitive blow molding solutions and comprehensive lifecycle support to our customers.

Leave a Reply

Want to join the discussion?Feel free to contribute!