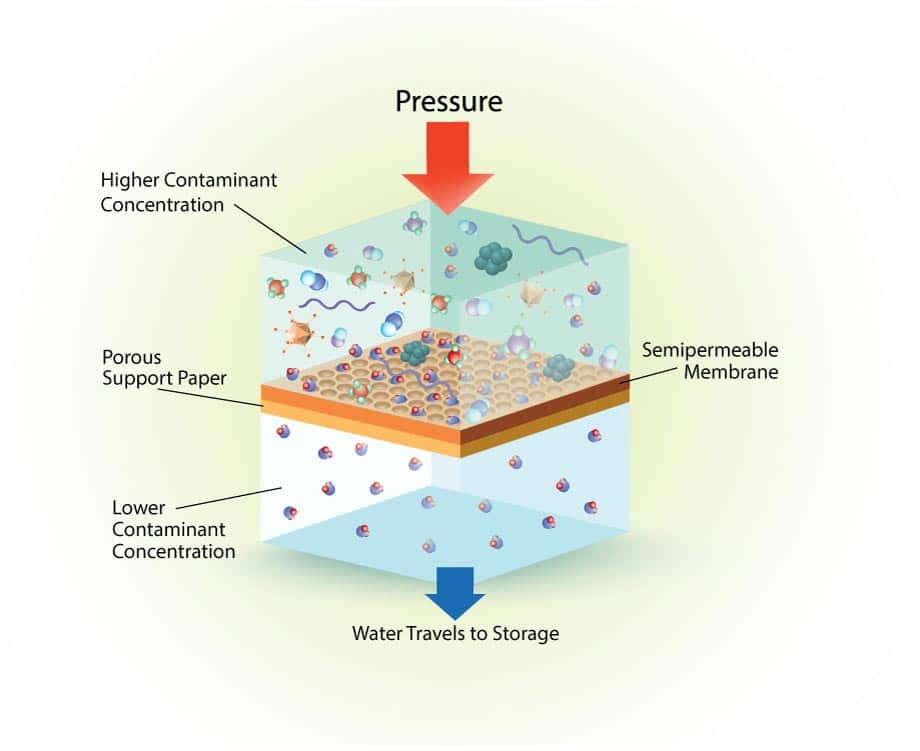

How RO Membranes Achieve 99% Contaminant Rejection

The essence of reverse osmosis (RO) membrane technology is a reverse breakthrough of the natural osmosis phenomenon. By applying an external force exceeding the osmotic pressure (usually 6 to 20 kilograms of pressure), water molecules in the water source are forced to pass through the semi-permeable membrane with selective permeability in the opposite direction, while dissolved solids, organic matter and microorganisms and other pollutants are retained and discharged. The core lies in the precise structure of the membrane material – the surface of the polyamide composite membrane presents nano-scale concave-convex wrinkles, and the transmission channels formed by these wrinkles have the dual functions of size screening and charge repulsion.

The removal capacity of modern RO membranes for specific pollutants shows differentiated characteristics: the retention rate for divalent ions (such as sulfate) can reach 99.7%, and the retention rate for monovalent ions (such as chloride ions) is approximately 95-98%. This difference stems from the interaction between the ionic hydration radius and the charge intensity. It is worth noting that the removal of free small molecule substances (such as boron and nitrate) by RO membranes requires special membrane materials or process combinations to be achieved.

In actual system design, the anti-pollution performance of membrane elements directly affects the operating cost. The anti-pollution film adopted by ShineDew reduces the surface roughness of the film (Ra value ≤40nm) and introduces a hydrophilic modification layer, making it difficult for pollutants to adhere. In combination with its intelligent control system, the recovery rate (50-75%) is dynamically adjusted according to the influent water quality, ensuring the membrane life while maximizing the water production efficiency. This combination of technologies reduces the system cleaning frequency by 40%, significantly enhancing operational economy.