Navigating the Blueprint of a Bottled Water Enterprise: From Source to Shelf

The global demand for bottled water continues to surge, driven by urbanization and an increasing consumer focus on health and hygiene. However, entering the bottled drinking water industry is not merely about “filling a bottle”; it is a sophisticated engineering journey that requires a perfect synergy between chemistry, mechanics, and regulatory compliance. Whether you are planning a still water line or a complex Carbonated Soft Drink (CSD) facility, success lies in the details of the process.

1. The Science of the Source: Water Treatment

Every successful bottling plant begins with a rigorous analysis of the source water—be it municipal tap water, underground boreholes, or surface water. Scientifically, we focus on TDS (Total Dissolved Solids), microbial load, and mineral balance.

For instance, a standard purification system involves multi-media filtration (quartz sand and activated carbon) followed by Reverse Osmosis (RO) or Ultrafiltration (UF). In the case of premium mineral water, we often utilize ozone sterilization and UV units to ensure microbial stability without stripping the water of its natural character. The goal is to meet WHO guidelines or local FDA standards, ensuring the product is chemically stable and biologically safe for a long shelf life.

2. The Core of the Line: Precision Filling Technology

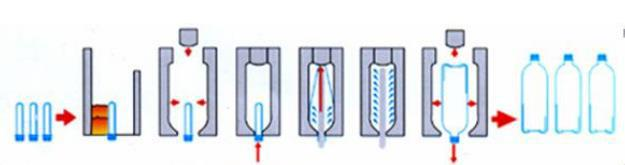

The “heart” of your factory is the filling monobloc. For carbonated beverages, the technical challenge escalates. We utilize Isobaric (Equal Pressure) Filling technology. This process involves pressurizing the PET bottle with CO₂ to match the pressure in the filling tank before the liquid enters. This prevents the escape of CO₂ and minimizes foaming—a common issue that can lead to inconsistent fill levels and product waste.

A critical detail often overlooked is the Filling Temperature. For carbonated drinks, maintaining a temperature of 0–5°C is essential for maximum CO₂ solubility. This requires an integrated cooling system, such as a high-efficiency Air-Cooled Chiller and a Plate Heat Exchanger, to ensure that every sip delivers that refreshing “fizz” the consumer expects.

3. Downstream Automation and Aesthetic Integrity

Once the bottle is filled and capped, the “after-process” determines the brand’s market appeal. Modern lines utilize Automatic Sleeve Labeling and Steam Shrink Tunnels for a 360-degree branding surface. For cold-filled bottles, a Bottle Warmer is a scientific necessity; it raises the bottle temperature to ambient levels to prevent condensation, which would otherwise compromise the integrity of the secondary packaging (shrink film or cardboard boxes).

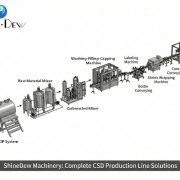

4. How We Empower Your Vision: Turnkey Solutions

At our core, we don’t just sell machines; we engineer solutions. We understand that a 2,500 BPH (Bottles Per Hour) line for a startup requires a different philosophy than a 24,000 BPH high-speed facility.

Our Value Proposition Includes:

Customized System Design: We provide detailed layout drawings tailored to your factory’s dimensions, optimizing the “U-turn” or “Linear” flow to reduce labor costs.

Integrated Preparation Systems: From steam-jacketed sugar melting tanks to high-precision CO₂ mixers (like our QHS series), we ensure your recipe is executed perfectly every time.

Rigorous Hygiene Protocols: Our equipment is built with SUS304/SUS316 stainless steel and is fully compatible with CIP (Clean-in-Place) systems, allowing forautomated sterilization of the entire fluid path.

Starting a bottling plant is a capital-intensive decision. By partnering with a provider who understands the nuances of water chemistry and mechanical synchronization, you mitigate the risks of downtime and product recalls. We invite you to consult with our engineering team to transform your raw water source into a market-leading beverage brand.